Thorough steel roof inspections in Peterborough, ON, follow industry standards set by CCS and NRC. Experts use advanced tools like laser scanners and magnifying glasses to evaluate joint integrity, corrosion, and structural soundness. Visual assessments, detailed documentation, and safety gear are crucial for identifying defects, guiding maintenance, and ensuring the longevity and aesthetic appeal of steel roofs in commercial and residential properties.

In the realm of property maintenance, meticulous steel roof inspections in Peterborough, ON, are paramount for ensuring structural integrity and safety. This comprehensive guide delves into the art of conducting thorough evaluations, covering essential standards, tools, and techniques. From visual assessments identifying common issues to meticulous documentation, each step ensures optimal roof health. Safety is paramount, and this article equips professionals with the knowledge to navigate inspections seamlessly while upholding the highest standards in Peterborough, ON.

- Understanding Steel Roof Inspection Standards

- Essential Tools for Precise Evaluation

- Visual Assessment: Identifying Common Issues

- Measuring and Documenting Defects

- Ensuring Safety During the Inspection Process

Understanding Steel Roof Inspection Standards

When it comes to conducting thorough inspections, especially for steel roof structures in Peterborough, ON, adhering to established standards is paramount. These standards ensure the safety and longevity of steel roofs, which are known for their durability and low maintenance requirements. In Canada, particularly Ontario, organizations like the Canadian Construction Standards (CCS) and the National Research Council (NRC) provide comprehensive guidelines specific to metal roofing inspections.

In Peterborough ON, professionals performing steel roof inspections must pay close attention to details such as joint integrity, corrosion levels, and overall structural soundness. The inspection process involves meticulous evaluation of fastening mechanisms, panel alignment, and potential water penetration points. By following these stringent standards, experts can identify and address issues early on, ensuring the optimal performance and aesthetic appeal of steel roofs in various commercial and residential properties across the region.

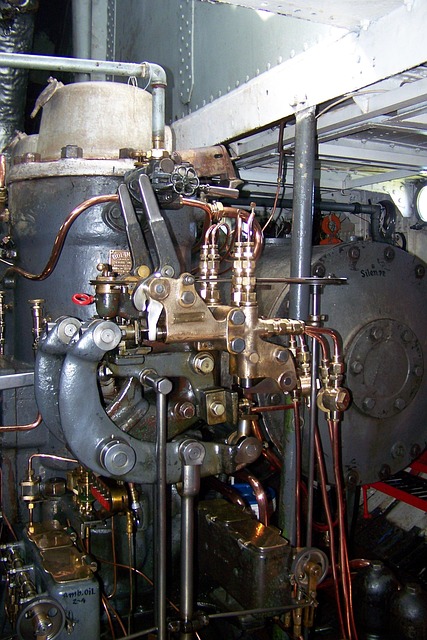

Essential Tools for Precise Evaluation

When conducting thorough inspections, especially for a steel roof in Peterborough, ON, the right tools can make all the difference. High-quality, specialized equipment is essential for precise evaluation and ensuring every detail is captured. Digital measurement tools, such as laser scanners and 3D imaging software, allow inspectors to record accurate dimensions, identify anomalies, and create detailed digital models of the roof structure. These advanced technologies provide an in-depth analysis, enabling professionals to detect even the subtlest defects or areas of concern.

Additionally, durable and precise hand tools are indispensable for close inspection. This includes robust tape measures, level probes, and magnifying glasses for examining intricate details. Magnets can also be useful for checking metal integrity and identifying loose or missing components. These essential tools empower inspectors to conduct thorough assessments, ensuring the safety, durability, and overall quality of steel roofs in Peterborough and beyond.

Visual Assessment: Identifying Common Issues

During a steel roof inspection in Peterborough, ON, one of the initial steps is a thorough visual assessment. This involves carefully examining the entire roof surface for any visible signs of damage or deterioration. Common issues that can be identified include rust spots, particularly around fasteners and edges, as well as dented or missing panels. Visual inspections also help to assess the overall condition of the roofing structure, looking for loose or damaged components that could compromise the integrity of the roof.

By focusing on these visual cues, professionals can quickly pinpoint problem areas, enabling them to conduct more detailed checks using specialized equipment. This precision focus ensures that minor issues are not overlooked, allowing for proactive maintenance and repairs before they escalate into costly replacements or safety hazards.

Measuring and Documenting Defects

During a steel roof inspection in Peterborough, ON, meticulous documentation is key. Inspectors should meticulously measure and record every defect found, ranging from minor cracks to significant structural anomalies. High-quality photographs capturing various angles are essential to provide clear evidence of issues. Alongside visual aids, detailed descriptions outlining the nature, severity, and location of defects enhance the accuracy of the inspection report. This comprehensive approach ensures that any potential problems are not overlooked, empowering property owners and managers to make informed decisions regarding repairs or replacements.

Accurate defect documentation enables effective comparison over time, aiding in tracking the progression (or regression) of roof conditions. This is particularly valuable for steel roofs, known for their durability but not immunity to corrosion, leaks, and other age-related deteriorations. By maintaining detailed records, professionals can demonstrate professionalism, enhance client trust, and contribute to better maintenance strategies for Peterborough properties.

Ensuring Safety During the Inspection Process

During a steel roof inspection in Peterborough, ON, safety should be the paramount concern for all parties involved. This involves ensuring that both the inspector and any occupants or nearby individuals are protected from potential hazards. Proper safety gear, including hard hats, high-visibility vests, and sturdy footwear, is essential equipment for anyone participating in the inspection process. Additionally, a thorough understanding of the building’s layout and any known structural issues beforehand can help inspectors navigate safely and efficiently.

Implementing meticulous safety protocols also includes identifying and mitigating risks unique to steel roofs. These may include precarious access points, exposed metal edges, or signs of corrosion that could pose a danger. By adhering strictly to industry standards and best practices for steel roof inspections, professionals in Peterborough can guarantee a comprehensive evaluation while prioritizing the well-being of all personnel.

Thorough inspections of steel roofs in Peterborough, ON, are essential for maintaining structural integrity and ensuring safety. By understanding industry standards, investing in the right tools, and meticulously assessing visual cues, professionals can identify and address common issues effectively. This process involves precise measurement, detailed documentation, and adherence to safety protocols. Armed with this knowledge, homeowners and contractors alike can confidently manage their steel roof assets, promoting longevity and peace of mind.